Optimisation/audit of E-filter – reducing the dust content and energy saving

The optimization/revision of your E filter is done step by step.

Optimization means for us that the separation-of-off values are better than the legal requirements, the mechanical components of your E filter will be protected and therefore longer duration be reached.

-

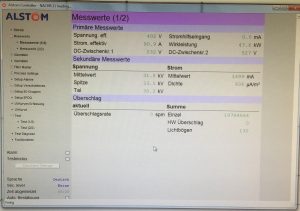

Determine the is status of filter control and the high-voltage equipment.

- -Functional testing of electrical equipment

- -Trials simulate (if possible)

- -Runs perform (cold commissioning, stress test, etc.)

-

- -Evaluation of existing data

-

-

Depending on the result of the condition creating an improvement concept.

This report will tell you exactly which control offers the optimum control on your investment for your ESP. If necessary, we can offer you a free 3-month trial operation with a modern filter voltage regulator. We also offer the integration of and control all auxiliary drives. This state of the art automation techniques are used. All functions can be visualized on an external display in the control cabinet.

-

Delivery and installation

The delivery of a modern filter control system, which is tailored to the conditions of your system, can take between 2 and 40 weeks, depending on the model.

-

Implementation of the renovation

We will carry out the conversion work as quickly as possible according to your deadlines with professionally qualified personnel , as every hour of the plant shutdown costs you as an entrepreneur a lot of money.

-

Monitoring of commissioning

Upon completion of the works and technical acceptance, we will monitor the plant with one of our service technicians, to possible nor correct variables in the entire flue gas cleaning locally or to discuss with your coworkers in the plant room. Should delayed the commissioning due to other system components, we come gladly to later again to you in the work. This point is not applicable only if you expressly absolve us from this.

-

A detailed documentation

After commissioning, a complete documentation (E-Plan, PDF, DXF, etc.) created. This will give you mostly advance emailed as a PDF file. Of postal delivery then few days later both in paper form and on CD.

Training of your personnel

For us, of course includes a detailed and comprehensive training of your personnel on the new control system components.

Spare parts for your ESP

Of course, we also offer you the procurement and professional installation of spare parts for your electrostatic precipitators . Contact us on it.

Repair of printed circuit boards

Unfortunately, older control boards are often discontinued, although still plants are in operation. In these systems, we are specialized to repair defective boards.